New AirPol Acid Gas Absorption Scrubbing System

AirPol has recently completed the supply of an Acid Gas Absorption Scrubbing System for Bayer CropScience through Process Combustion Corp, Pittsburgh, PA. The equipment is being installed in the Bayer, Kansas City, MO plant on the exhaust from a waste stream thermal oxidizer. AirPol has supplied over 40 such systems over the last 30 years to many pharmaceutical and chemical companies throughout the U.S.

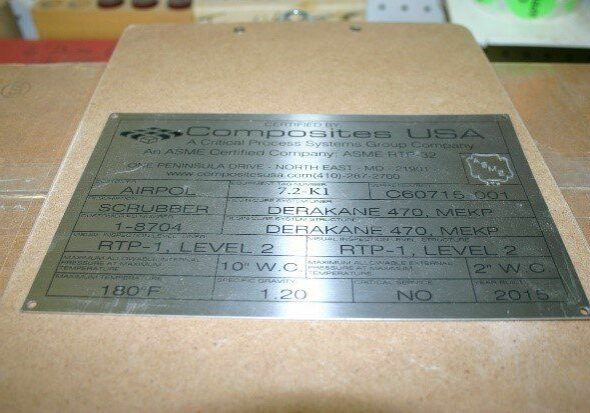

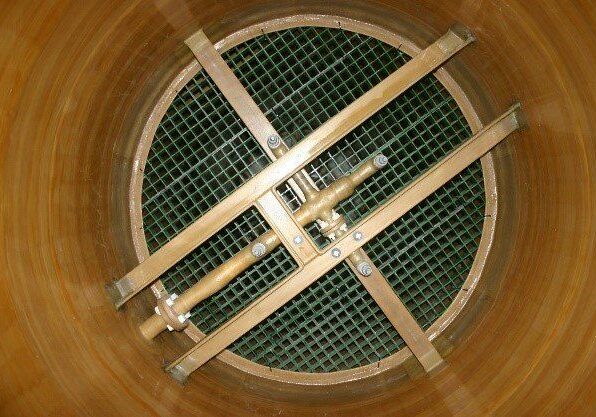

This application is for control of hydrochloric (HCl) and hydrobromic (HBr) acid emissions. Due to the corrosive nature of the acid gases and the recirculated scrubbing liquid, the materials of construction were selected to provide an extended service life in an environment where the typical stainless steels would not stand up to high chloride and bromide salt concentrations. Alloy AL6XN was used for the Quench (Elbow) Duct that receives and cools the hot gases from the oxidizer. Downstream of the Quench Duct fiberglass and thermoplastic construction was utilized for the absorption vessel and its packed section and mist eliminator internals. An exhaust stack mounted on top of the Packed Absorber outlet is guided for wind forces by a structural steel tower that also provides access to manways and test ports. Due to very stringent Plant quality control specs and requirements, all-fiberglass construction was done in accordance with ASME RTP-1 standards and protocol.

Like many chemical manufacturers, this Plant’s expectations and approval process were very demanding. AirPol’s rep in this case (Jim Stetson, Kahl-Stetson) played an important role in assisting with resolving various project obstacles as well as equipment detail concerns that arose in the Plant’s review and critiquing of the long-standing and proven AirPol design approach. While this type of project is normally completed within a 6-7 month time period, this one extended out to almost 18 months. A very challenging project was successfully completed with a team approach. We thank Jim for his efforts in getting this one done.

Construction Site, Kansas City

Custom Engineered Components and Systems provide the best Air Pollution Control Solutions

Custom engineering of air pollution control systems to suit the conditions and characteristics of each application is the key to ensuring the best possible performance. Each installation needs to handle a unique combination of exhaust gas characteristics, contaminants (particulate and gaseous) and then provide the desired removal efficiencies.

With wet scrubbers, these factors affect the techniques employed to wet surfaces, saturate the gas stream, capture/remove the contaminants, and subsequently separate droplet entrainment prior to clean gas being discharged to the atmosphere. Standardized equipment and modular design do not help much in this regard and serve merely as a starting point for the design.

The best custom engineered wet scrubber systems match different components and control strategies. Experience is a vital component in this effort. The engineers at AirPol, Inc. have this experience, having had hands-on experience with over 1000 installations over the last 40 years.