WET ELECTROSTATIC PRECIPITATORS (WESPs)

Wet electrostatic precipitators, or WESPs, use charged rods to create a field that pulls particulate from dirty flue gases to collection tubes that are continuously flushed with condensation.

WESPs have a unique design benefit of being able to grab the very fine particulates and mists from the airstream, which makes it an ideal polishing step in an air pollution control system.

The energy demand and pressure drops across WESPs are relatively low, which makes retrofits and add-on final control installations cost-effective.

Wet Electrostatic Precipitator Design Features

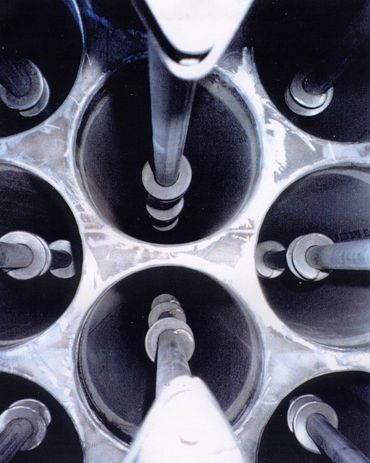

- Tubular configuration allows self-irrigation without high water-flow rates.

- On-line cleaning allows continuous efficient operation.

- High secondary power levels produce increased collection efficiency for submicron particulate, heavy metals, and mist.

- Rigid discharge electrode with sharp emitting points results in intensified corona fields.

- WESPs are easily incorporated into systems with pre-scrubbing equipment.

AirPol Advantages

- Our Wet Electrostatic Precipitators has superior performance, even with high concentrations of sub-micron particle loading

- operates effectively, even with high current suppression

- very high-intensity corona

- low system energy requirements WESP Internals smooth

- lower water requirement

- rigid electrodes with precise alignment

- flexible downflow or upflow designs to suit the system arrangement

- low maintenance requirement

Applications

- heavy metal and salt fume removal from industrial and hazardous waste incinerators

- smoke and fume removal from industrial processes

- fine dust removal and organic pollutants

- acid mist removal from boilers and industrial processes

Satisfied Customer: Lenzing Fibers

Lenzing Fibers, located in Axis, Alabama, was investigating ways to lower the opacity of its exhaust system and increase recovery of solvent from its regenerated cellulose fiber (“Tencel”) production process. The performance of existing mist eliminators was not sufficient to adequately impact the very small particulate size.

AirPol was awarded a contract to supply and install a new Wet Electrostatic Precipitator (WESP) system that included inlet and outlet ductwork, control dampers, and a booster (exhaust) fan and exhaust stack, as well as a WESP Control Panel and instrumentation.

The turnkey project was completed using Lenzing’s preferred local contractors. The existing mist eliminators were removed and the new system easily provided the expected results. So much so that when Lenzing decided to re-start a second (idle) production line, another companion AirPol WESP system was purchased to ensure similar performance.